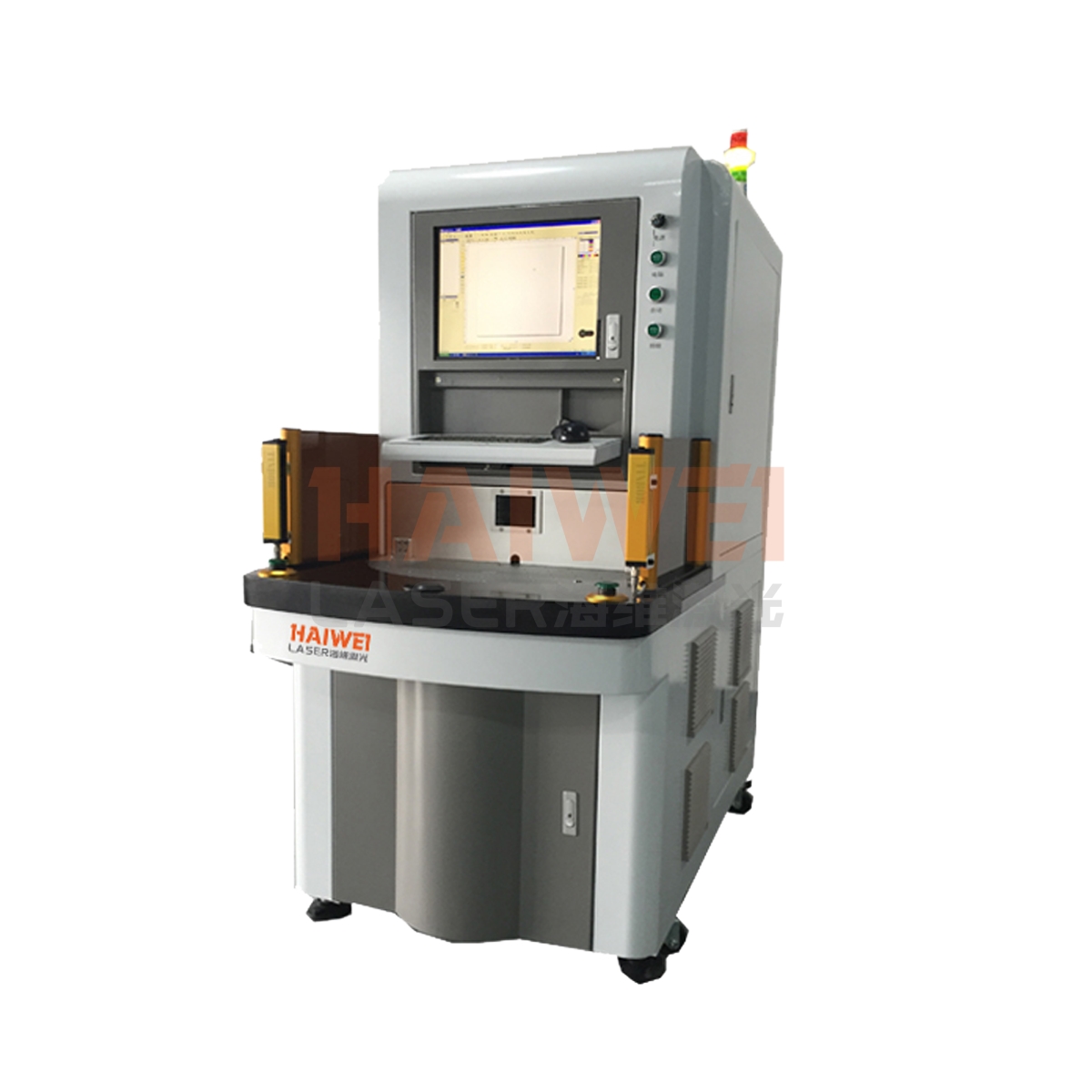

Product Series:UV laser marking machine

Technical Support:Customizable

Application field:Ultra-fine processing high-end market, marking of packaging bottles of cosmetics, medicines, food and other polymer materials

Ultraviolet laser has a very small focus spot and a small processing heat-affected zone, so it can be used for super-fine marking and special material marking. It is the first choice for customers who have higher requirements for marking effects. Zixibu laser copper removal material In addition, suitable for adding

The material of the work is more extensive.

It is mainly used in the high-end market of ultra-fine processing, marking the packaging bottles of cosmetics, medicines, food and other polymer materials, with fine effects, clear and firm markings, due to ink printing and pollution-free marking and dicing of flexible PCB boards; silicon crystal

Wafer micro-hole and blind hole processing; LCD LCD glass two-dimensional code marking, glassware surface punching, metal surface coating marking, plastic buttons, electronic components, gifts, communication equipment, building materials, etc.

| Model | HW-UV-3 |

| Power | 3W |

| Laser wavelength | 355nm |

| Beam quality M2 | M2:<1.1 |

| Q frequency | 5-100KHZ |

| Mark range | 100*100mm |

| Marking line speed | 7m/S |

| Minimum line width | 0.015mm |

| Repeat accuracy | +-0.02mm |

| Cooling method | 风冷 |

| Total power | 1000W |

| Electricity requirements | AC2200V/50Hz |

Haiwei laser welding equipment is directly sold by the factory. It has 17 years of resource advantage, and the same performance and quality are more favorable, which fully benefits customers and achieves win-win development.

Provide consulting, diagnosis, optimization, maintenance and other services, and respond 24 hours a day, according to customer needs and produce customized products and solutions.

The mature after-sales service system allows customers to purchase with confidence, humanized service support, free proofing, installation training, upgrade and debugging, etc. to meet the diverse needs of customers.

Software and hardware are independently developed and designed, with mechanical design, software programming, electrical automation, parts processing, assembly and debugging, and after-sales teams, which can provide customers with professional maintenance, parts replacement, product upgrades and other technical services, and continue to create value for customers .