Free proofing

Independent R&D and design of software and hardware, factory direct sales service guarantee

17 years of full value chain system to create greater value for customers

After 17 years of product R&D and intelligent manufacturing applications, Haiwei Laser has in-depth cooperation with global industry partners from the procurement of raw materials and core components to the introduction of cutting-edge technology to continuously optimize and improve the entire value chain system. A 17-year full value chain system, creating greater value for customers Targeting the market and customer needs, combining production, marketing, research and service integration mechanisms, giving full play to the advantages of industrial resources, saving customers more costs and creating greater benefits

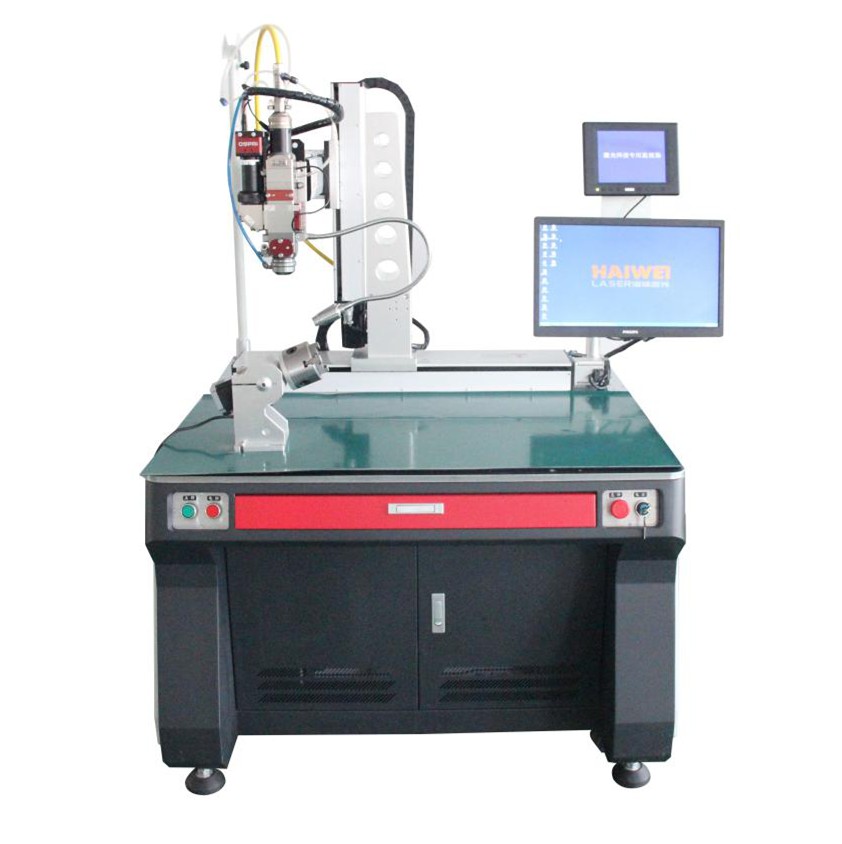

Laser welding automation system product & solution supplier service provider

Shenzhen Haiwei Laser Technology Co., Ltd. is a high-tech enterprise specializing in industrial precision laser welding, laser marking, and laser cutting, integrating R&D, production, sales and service. With 17 years of professional laser welding system research and development and industry application experience, with a professional technical research and development team, to provide professional automated laser welding system products and solutions.

6

Top 500 customers

17years

Industry experience and strength

23 items

Patent intellectual property

- Won the title of China's preferred brand in the CCTV laser equipment industry

- Haiwei Laser passed the ISO9001 quality management system certification

- Passed CE/FC/ROHS and other safety and quality certifications

- The marketing services of the two branch companies and the Shenzhen headquarters spread across the country

- Send R&D teams abroad to exchange and study every year

Cutting-edge technology news, Haiwei shares with you

The annual SIMM Shenzhen Machinery Exhibition is themed on metal processing. The Shenzhen Machinery Exhibition is also an important stage for laser processing equipment manufacturers. What excellent products have we brought to you this time? Next, the editor will take you to see what products Haiwei Laser brings this time. As everyone knows, with the advancement of science and technology and social development, more and more advanced technologies have been applied to industrial manufacturing. As a modern processing technology, laser technology plays a huge role in industrial production, not only greatly improving production efficiency, but also driving the development of related industrial chains. Intelligent manufacturing 2025 has become the main theme of current industrial development. The application of lasers is gradually developing in the direction of greater power, faster speed, and smarter production. The rapid development of the consumer electronics market also puts forward higher requirements for processing accuracy. Laser precision processing Technology faces more opportunities and challenges. Our Haiwei…

Dear friends and colleagues: We sincerely invite you to visit the 7th Electronic Information Expo which will be grandly held in Shenzhen Convention and Exhibition Center on April 9, 2019. The main contents of this expo include digital homes, devices, new displays, ICs, artificial intelligence, and automobiles. The core content of the development of the eight major electronic information industries, 5G, Internet of Things, and intelligent manufacturing. Through the CITE theme pavilion, new display pavilion, intelligent manufacturing and 3D printing pavilion, robot and intelligent system pavilion, artificial intelligence pavilion, 5G and Internet of things pavilion, automotive electronics, smart driving and lithium battery energy absorption pavilion, and electronic components The 25 professional exhibition areas, including the museum, fully demonstrated the latest development achievements and trends of the electronic information industry in the intelligent era, and created a first-class international electronic information field display platform.

Is laser welding harmful to the human body? I believe that many of my friends are more concerned about this issue. Today, I will introduce the impact of laser welding on the human body. Laser deep penetration welding can thoroughly penetrate the workpiece, and has large input energy and fast welding speed. It is currently the most widely used laser welding mode. This method is undoubtedly a more convenient way of welding. Laser welding machines can generally be divided into heat conduction welding and deep penetration welding. The heat of the former diffuses into the workpiece through heat transfer, and only melts on the surface of the weld. The interior of the workpiece is not completely penetrated, and vaporization is basically not generated. It is mostly used at low speeds. Welding of thin-walled materials; the latter not only completely penetrates the material, but also vaporizes the material to form a large amount of plasma. Due to the large heat, a…

Fiber laser marking machine is a commonly used model in the marking industry now. The use of fiber laser laser marking materials is clear and exquisite without loss, so it has been favored by most users. At present, the price of fiber laser printers on the market is as low as 40,000 to 50,000, and the expensive one is more than 200,000. If you accidentally buy a low-quality fiber laser marking machine, it will not only waste a lot of money, but also seriously affect your work. schedule. So how to choose a fiber laser marking machine? I believe this is a question that customers who are interested in buying a fiber laser marking machine are very concerned. The editor tells everyone how to distinguish the quality of a fiber laser marking machine.

Analysis of disadvantages of laser welding machine and argon arc welding machine. First of all, laser welding laser welding machine is a kind of high-energy beam welding. Generally, laser welding equipment is used for welding. Laser welding uses high-power coherent monochromatic photon beam to focus laser beam for heat source welding. . The advantage is that the energy control can be performed accurately when needed in a vacuum, so a precise connection device can be realized. It can be widely used in many of our different metals, especially to solve the welding of some difficult-to-weld metals and dissimilar metals.

In addition to the performance and comfort of the car itself, the sales level of a car is whether the car body design attracts consumers’ attention. In the process of car body design and production technology manufacturing, laser welding is currently one of the important process methods in automobile manufacturing. Through laser welding, the accuracy of the combination is further improved, the hidden dangers in the car are reduced, and the safety and comfort are improved. The car’s outer shell greatly increases the rigidity and strength, and can also reduce the noise when prompting the safety of the car.

As far as I know, this company has processed 3C electronics, metal stamping, plastics, food, and medicine. There are also many high-quality cases for reference on the official website. You can go and see.

This is the service problem of the manufacturer. It is recommended to find a professional and good-service manufacturer to cooperate. You can choose Shenzhen Haiwei Laser. After the shipment, Haiwei Laser will have professional installers. On-site installation and teaching, if you encounter any problems during use For questions, you can call the after-sales number of Haiwei Chengshiwei. Haiwei Chengshiwei after-sales team will provide you with efficient services. The company’s purpose is to serve you until you are satisfied.