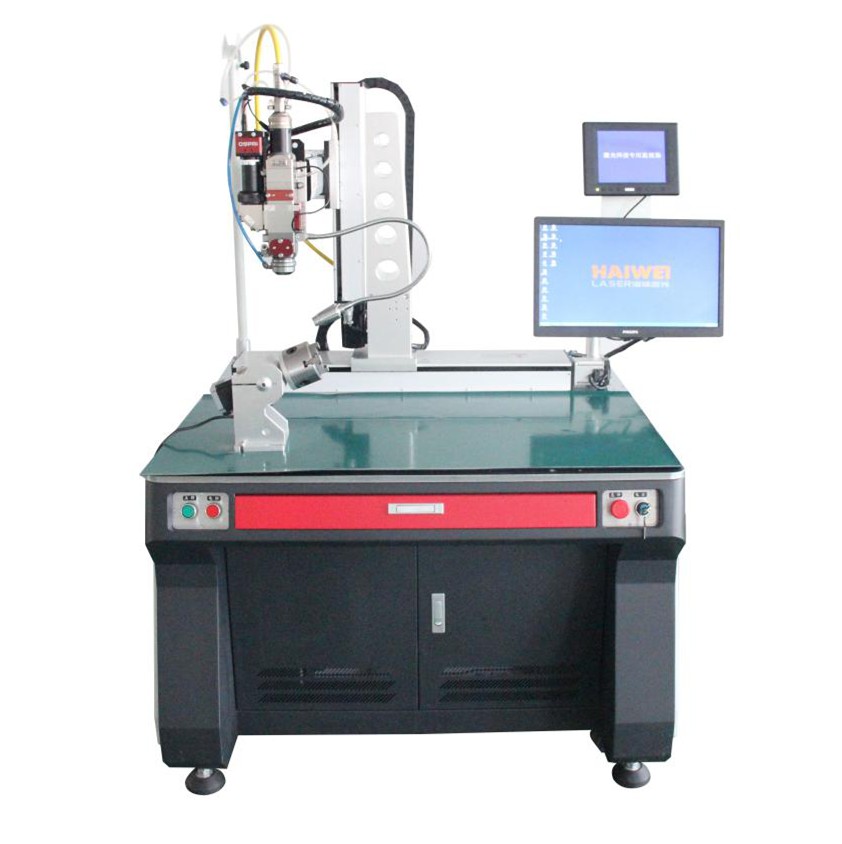

Product Series:Continuous fiber laser welding machine

Technical Support:Customizable

Application field:Batteries, consumer electronics, solar panels, auto parts, hardware kitchenware, medical equipment, sensors, molds, jewelry, glasses, stainless steel doors and windows and other industries

Using 1000-3000 watt fiber laser, high electro-optical conversion efficiency, long laser life, intelligent operation, flexible and reliable, equipped with domestic leading welding module, to achieve more precise and perfect welding. The intelligent operation platform is more flexible, more automated and more efficient. The CCD liquid crystal monitoring and inspection system can clearly observe the product positioning and welding effect according to the red light instructions. Automatic welding seam tracking system, real-time tracking of the shape of the welding seam, and timely correction of the position of the welding torch according to the condition of the welding bead, realizing precise welding and a more beautiful welding surface. The exclusive patented welding technology of HW series is more suitable for welding workpieces with relatively wide welding seams. Welding applications are more extensive, and it can realize precise welding for larger workpieces and competing welding seam workpieces.

Strong adaptability and wide application. More typical application areas: batteries, consumer electronics, solar panels, auto parts, hardware kitchenware, medical equipment, sensors, molds, jewelry, glasses, stainless steel doors and windows and other industries.

Carbon steel, stainless steel, aluminum, copper, nickel, titanium, silver, gold, platinum, alloys and other materials.

| model | HW-FWT1000-A | HW-FWT2000-A | HW-FWT3000-A |

| Requirements of power supply | AC380V/±10%,50Hz | AC380V/±10%,50Hz | AC380V/±10%,50Hz |

| equipment power | 4KW | 8KW | 12KW |

| Laser power | 1000W | 2000W | 3000W |

| Wavelength | 1080nm | 1080nm | 1080nm |

| Work area | X-800mm,Y-400mm,Z-300mm R-360 (工作行程可以定制) | ||

| input/output | I/O RS232 | ||

| Localization way | Red diode indicator (option ccd) | ||

| Welding depth | 2.0mm(sus304) | 3mm(sus304) | 3mm(sus304) |

| Cooling way | Water chiller | ||

Haiwei laser welding equipment is directly sold by the factory. It has 17 years of resource advantage, and the same performance and quality are more favorable, which fully benefits customers and achieves win-win development.

Provide consulting, diagnosis, optimization, maintenance and other services, and respond 24 hours a day, according to customer needs and produce customized products and solutions.

The mature after-sales service system allows customers to purchase with confidence, humanized service support, free proofing, installation training, upgrade and debugging, etc. to meet the diverse needs of customers.

Software and hardware are independently developed and designed, with mechanical design, software programming, electrical automation, parts processing, assembly and debugging, and after-sales teams, which can provide customers with professional maintenance, parts replacement, product upgrades and other technical services, and continue to create value for customers .