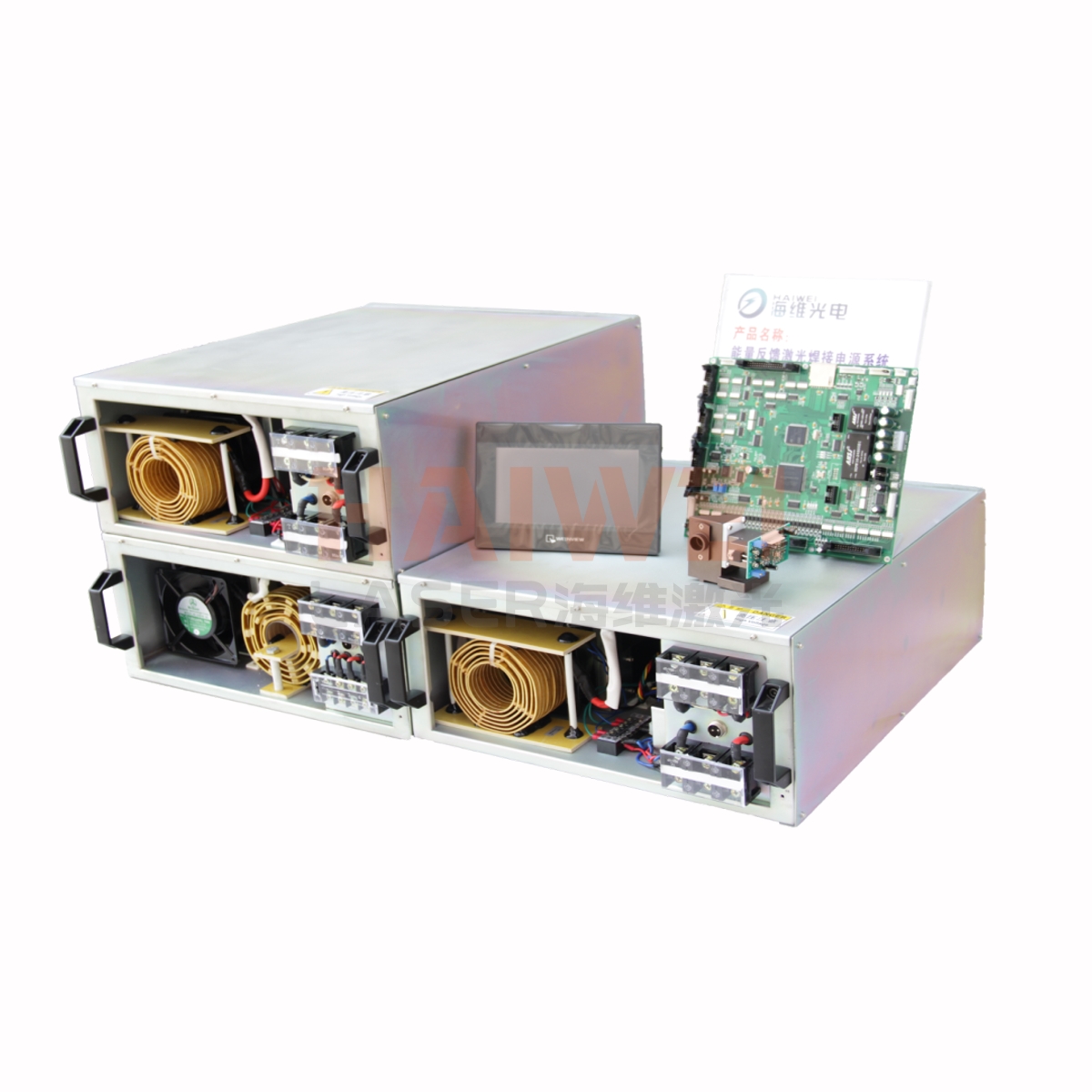

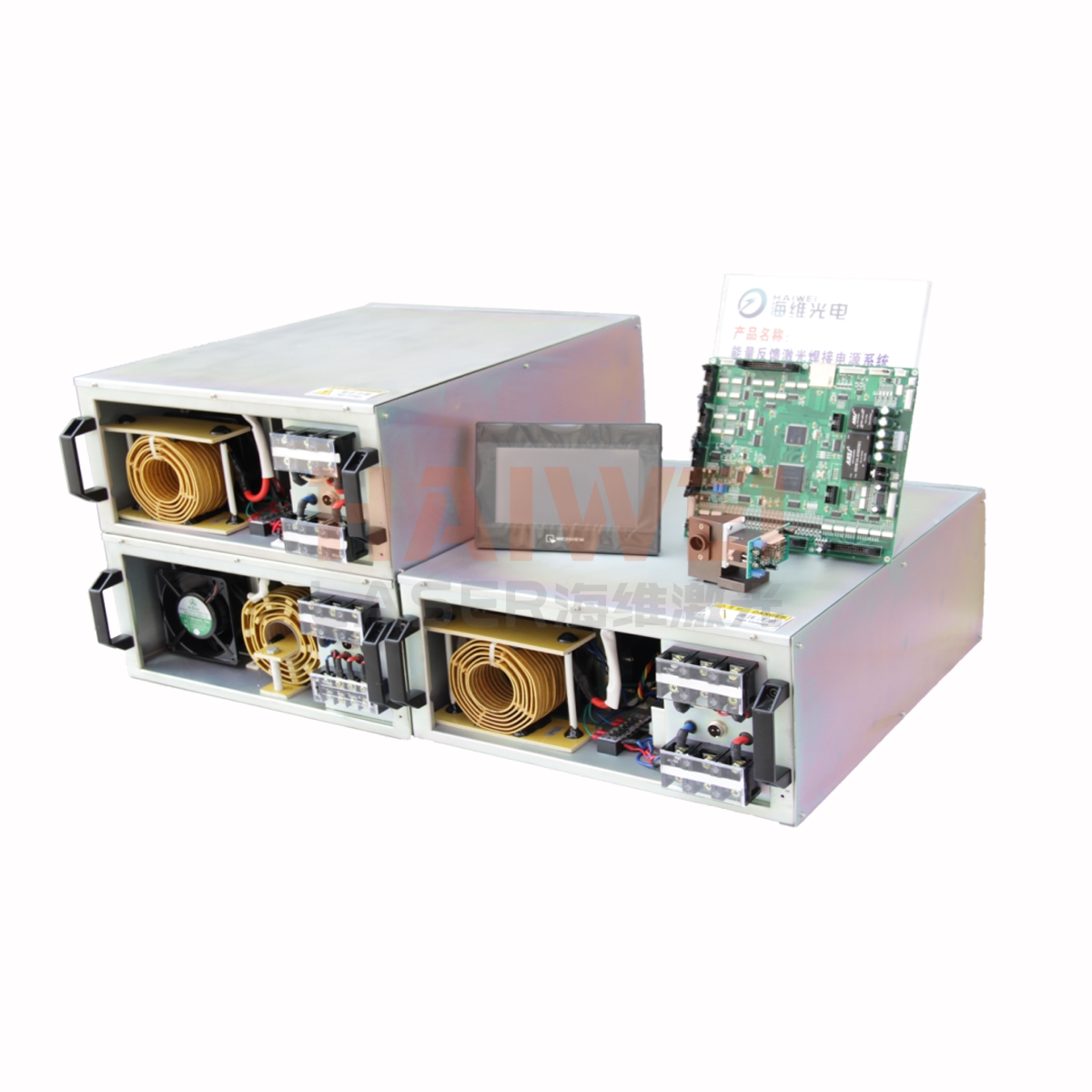

Product Series:Energy feedback laser welding power system

Technical Support:Customizable

Application field:Mobile phone communications, electronic components, glasses and watches, jewelry, hardware, precision equipment, medical equipment, auto parts, power batteries, craft gifts and other industries

HW series laser welding power supply is a DSP controlled intelligent, high-precision constant current switching power supply independently developed by our company, with dual functions of laser energy feedback and current feedback, and can be used as a standard supporting power supply for lamp-pumped Nd:YAG pulsed lasers. The technical performance of this product is at a technologically excellent level in the domestic industry. The man-machine interface of the power supply is friendly, providing various working parameters and status displays. The user can set a variety of laser waveforms and parameters through the touch screen, and have various reports such as water temperature, water flow, 7K position, overcurrent, overvoltage, and lack of equality. Therefore, it can meet the needs of almost all laser welding applications. It is an ideal configuration for multi-function laser welding machines. 6 This series of laser pulse welding power supplies have different output powers according to different welding applications. They can be customized according to user needs. The power level is 18 kilowatts for dual lamps (optical power 600W).

It can be applied to the welding of titanium, nickel, tin, zinc, copper, aluminum, chromium, niobium, gold, silver and other metals and their alloys, steel, Kovar alloy and other alloys of the same material. It can also be applied to copper -Welding between nickel, nickel-titanium, copper-titanium, titanium-molybdenum, brass copper, low carbon steel_copper and other dissimilar metals. Widely used in mobile phone communications, electronic components, glasses and watches, jewelry, hardware products, precision equipment, medical equipment, auto parts, power batteries, craft gifts and other industries.

| Model | HW-W75E | HW-W150E | HW-W300E | HW-W600E |

|

Input voltage |

AC220v±10%,50Hz | AC380v±10%,50Hz | AC380v±10%,50Hz | AC380v±10%,50Hz |

| Power | 3KW | 6KW | 12KW | 18KW |

| Touch screen | 7 inch color screen | |||

| Max peak power | 6kw | 6KW | 10KW | 10KW |

| Pulse frequency | 0-100Hz | |||

| pulse width | 0-20Ms | |||

| Pulse energy | 1-35J | 1-40J | 1-70J | 1-100J |

| Feedback mode | Energy feedback | |||

| Energy feedback | ≤±1% | ≤±1.5% | ≤±1.5% | ≤±2% |

| Wavaform setting | Arbitrary Waveform set,1-20 point | |||

| Parameter storage | 8G SD memory, call 32 sets of parameters | |||

| Energy setting | Each point energy can be set | |||

| input/output | I/O RS232 | |||

| Test time | 100 million times test | |||

| Working environment | Temperature:5℃-35℃ humidity:5%-75% air dust<0.01g/cubic meters | |||

| L×W×Hsize | 570mm×430mm×200mm | 570mm×430mm×200mm | 570mm×430mm×200mm | 570mm×430mm×200mm |

Haiwei laser welding equipment is directly sold by the factory. It has 17 years of resource advantage, and the same performance and quality are more favorable, which fully benefits customers and achieves win-win development.

Provide consulting, diagnosis, optimization, maintenance and other services, and respond 24 hours a day, according to customer needs and produce customized products and solutions.

The mature after-sales service system allows customers to purchase with confidence, humanized service support, free proofing, installation training, upgrade and debugging, etc. to meet the diverse needs of customers.

Software and hardware are independently developed and designed, with mechanical design, software programming, electrical automation, parts processing, assembly and debugging, and after-sales teams, which can provide customers with professional maintenance, parts replacement, product upgrades and other technical services, and continue to create value for customers .